The Problem:

Studies have shown that wheelchair users are exposed to levels of vibration that are considered unsafe and that this can affect health and life quality 1 . This is a risk factor for all wheelchair users, increasing the amount of muscle fatigue and potentially damaging connecting nerves 2. This can be particularly acute for those with spinal injuries.

Manufacturers of wheelchairs have tried to address this issue by adding suspension or designing wheelchair frames from innovative materials. Unfortunately this has not fully addressed the problem, as wheelchairs with suspension only marginally improved vibration control but incurred a large weight penalty and an increase in frame costs 3. Carbon fibre showed some promise in frame design 4 but was very costly to manufacture.

The Solution:

At Loopwheels we have addressed this problem by using carbon composites to create an ‘in-wheel‘ spring that can absorb vibration, without the weight penalties of a suspension chair or the cost penalties of a full carbon frame.

Methods

To test vibration reduction qualities of the Loopwheel it was compared to a standard metal spoked wheel that is usually the original equipment found on a wheelchair.

The wheel was positioned directly over a vibration plate. The wheel was then loaded with a weight (10kg). An accelerometer is then positioned on the frame holding the load. The accelerometer measures the vibration coming through the wheel. Each wheel was then tested at three different frequencies (7, 10 and 13 Hz). This frequency range was chosen as this has been shown to be in the range of the most problematic frequencies for human health (1-20Hz) 5.

To make sure all comparisons were equal all wheels had the following specification:

- 24”wheel size with a bead seat diameter (BSD): 540mm

- ½” bearings, taken from the same production batch (manufactured by MBL)

- Schwalbe Marathon Plus tyres

- Schwalbe Schrader inner tubes

- Tyre pressure: 110 pounds per square inch (PSI)

- Black aluminium powder coated push rims (wide offset)

Results:

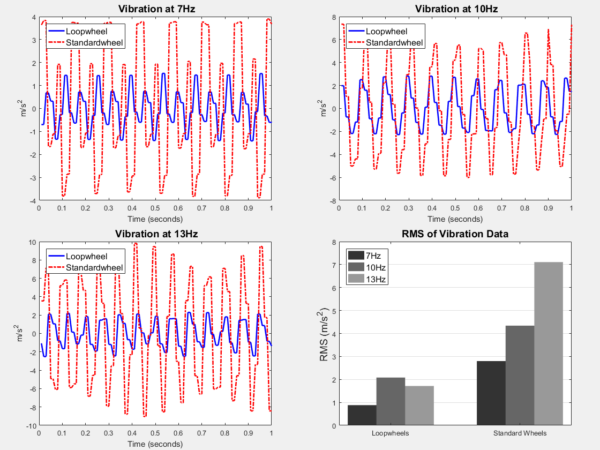

Raw acceleration data was plotted for all three conditions along with root mean square acceleration.

So How Much Do Loopwheels Reduce Vibration vs Normal Wheels?

The Solution:

The Loopwheels reduce vibration by 68% at 7Hz, 52% at 10Hz and 76% at 13Hz.

Overall Loopwheels significantly reduce the amount of harmful whole body vibrations a wheelchair user will experience through their rear wheels, this is turn can help to manage pain and fatigue and therefore allow a wheelchair user to travel further.

Other tests to be published shortly:

The rolling efficiency of the wheel.

- The vibration reduction efficiency vs other leading wheelchair wheels.

References

1. Vorrink SNW, Van Der Woude LH V, Messenberg A, Cripton PA, Hughes B, Sawatzky BJ. Comparison of wheelchair wheels in terms of vibration and spasticity in people with spinal cord injury. Assist technol Res Ser. 2010

2. Garcia-Mendez Y, Pearlman JL, Boninger ML, Cooper RA. Health risks of vibration exposure to wheelchair users in the community. J Spinal Cord Med. 2013

3. Kwarciak AM, Cooper RA, Fitzgerald SG. Curb descent testing of suspension manual wheelchairs. J Rehabil Res Dev. 2008;45(1):73-84. doi:10.1682/JRRD.2006.11.0142.

4. Chenier Felix, Aissaoui R. Effect of Wheelchair Frame Material on Users’ Mechanical Work and Transmitted Vibration. Biomed Res Int. 2014;2014. doi:10.1155/2014/609369.

5. Katu US, Desavale RG, Kanai RA. Effect Of Vehicle Vibration On Human Body – RIT Experience.